TECHNOLOGY INTERVENTION ON DIGITAL SUPPLY CHAIN

Amulu James Michael

Product Management, SAP Labs India Pvt. Ltd, India

10.21917/ijms.2018.0096

Abstract

Technology is no more a research labs thing and need to be applied to improve businesses and society. This means that when an invention makes relevance to society it need to be converted into innovation by absorbing into businesses. This paper focuses on technology disruptions that are relevant to supply chain across industries.

Keywords:Industrial Internet of Things, Machine Learning, Vendor Managed Inventory

1. INTRODUCTION

Today’s businesses faces enormous challenges such as technology, socio political factors, dynamic regulatory norms, compliance requirements, market expansion, slim margin, newer skill requirements and changing business models that impact businesses. The businesses need to stay relevant by finding ways to mitigate challenges and maintain edge by embracing technology. In this article the author covers various aspects of digitization which businesses need to consider for their advantage in supply chain space. The digitization of business is viewed as part of the Industry 4.0, IIOT, FinTech wave initiatives where in the industry and technology coming together to solve latency and to make it more vibrant and future ready.

2. WHY DIGITAL AND NOW?

Design thinking principle will help us find answers for these questions with its three pillars namely desirability, viability and feasibility. Design thinking is a framework to solve any problems and in business to make a big shift to exploit opportunity we need to know whether the time is right.

Design thinking helps technology adoption time and again as there is a desire and belief that technology helps to solve business problems. Technologies in the context of supply chain viability is gaining grounds with enough proof points beyond technology in laboratory conditions. Feasibility is an aspect and all technology vendors are coming together to address the problem for quicker adoptability into business making it affordable for businesses. By the design thinking principles, we have better coverage of all the three aspects make the case compelling to embrace technologies in supply chain as the lever of benefits are larger with technology to businesses. Newer business models are emerging due to technology influence which transforms traditional commodity buying into services buying such as buying compressors viz-a-viz buying quality compressed air and pay only for what you consume which removes ownership hurdles. Leading industry researchers around the world identify challenges faced by businesses in the current scenarios found that innovations are mandatory to disrupt the business with Industry 4.0 initiatives worldwide. The IIOT (Industrial Internet of Things), Blockchain and all other technologies in the context of this article are gaining pace with the regulatory, standards and architectures are evolving and put in place to make smoother adoption by businesses. You may find various opportunities identified by business researchers and few are discussed in the upcoming sections. Technologies are no more in pilot stage and there are applications of it into business and put into good use. The business benefits are measurable and encouraging making the CXO’s to consider technology infusion to gain business edge. The role of business heads is changing and the technology is no more a CIO’s responsibility. Business heads are empowered for decision-making and they collaborate with the technology companies in the journey of innovation with the business domain available at disposal for a common good cause. This collaboration across businesses quashes virtual boundaries, accelerates the innovation in many areas and helps capacity augmentation as the innovations on business with technology happens across business process and not in a linear way. Businesses no more hold only the manufacturing intellectual property but also hold technologies in business which are potential revenue earners as well. Industries are collaborating on revolutionary initiatives such as Industry 4.0, IIOT, Blockchain, etc. to get the standards defined which otherwise is a hurdle to implementations. The interesting piece of information what the businesses hold are data which they are willing to share to unlock value under Non-Disclosure Agreements (NDA) which was a general hindrance of technology companies who only have a vague idea on how the business data look like. This fills the gap of technology and domain with the collaboration of industries in innovations. There are co-innovation approaches adopted to have a clearly demarked boundary of Intellectual properties and the revenue share which prevents ground up everything to value lead innovation on the existing innovations. This also helps to overcome the gaps of competency and help augment each other’s competencies leveraged for common good. We need to remember that the business does not change whereas it’s becoming more and more dynamic with the help of technology which shatters the shackles of the silos.

3. DRIVERS OF DIGITIZATION

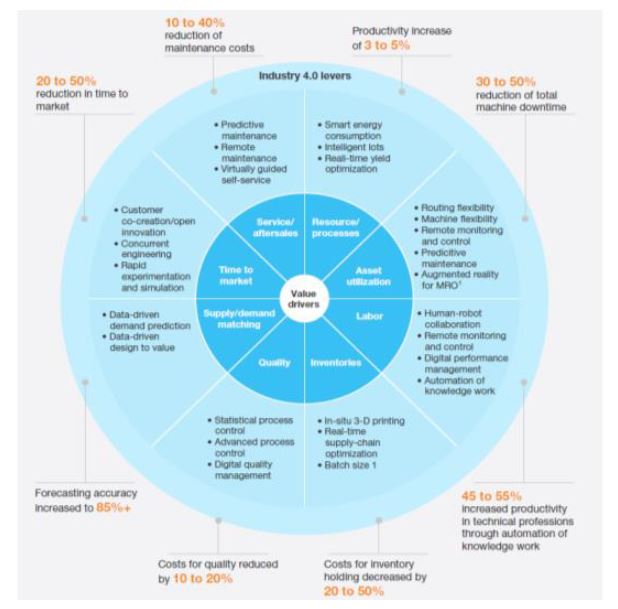

Digitization is the buzz word of businesses and everyone is trying to put an effort to leverage the benefits of digitization in to their businesses and industry. It is not a noise in isolation where as the industry is moving in this direction eyeing on the potential benefits this revolution could bring in to stay relevant. There are other initiatives which augments the digitization drive and the primary one is Industry 4.0. Various frameworks emerging out of extensive research and agencies and trying to help industry to narrow down the areas to focus. Following are some of the frameworks published by leading research houses such as McKinsey, PWC, SAP, etc. The research framework is an outcome of extensive interaction with various industry titans from different industries and their view points to achieve positive impact in this revolution.

The Fig.2 to Fig.4 indicate that the digitization is not a single business unit or the IT department’s function in an organization and it is an overall effort which brings in the benefits. This also highlights the relevance and importance of technologies and a potential application in supply chain management space.

4. SUPPLY CHAIN MANAGEMENT

Chandra and Grabis quotes “Chain Management involves various approaches utilized to effectively integrate suppliers, manufacturers, and distributors in performing the functions of procurement of materials, transformation of these materials into intermediate and finished products, and distribution of these products to customers in the right quantities, to the right locations, and at the right time to meet the required service level with minimal cost” [6]. Gerhard Oswald and Michael Kleinemeier in their book quotes “Supply chain management also involves managing a connected series of activities that is concerned with planning, coordinating, and controlling movement of materials, parts, and finished goods from the supplier to the customer. For this to occur, material, financial, and information flows are managed as decisions are made at strategic, tactical, and operational levels throughout the supply chain.” [5]

Michael Porter’s well established 7 supply chain management dimensions as below,

5. FRAMEWORK TO MAKE DIGITAL EVERYTHING [2]

5.1 DIGITAL CUSTOMERS

They expect technology to be applied on identifying Company’s selling and customers buying patterns, collaborative demand planning with the customers to re-design the demand planning processes, based on solutions and technologies using demand sensing, digital product history to provide additional services to customers such as predictive maintenance, trend mining based on social media signals and its usage in actual planning phase of marketing, pricing or promotion planning.

5.2 DIGITAL PRODUCTION SYSTEMS

It need to pay attention to high-volume equipment reliability analysis and many have first projects in preventive maintenance where they search for analytics capabilities to operationalize the large volume of data, Quality 3D printed production of spare parts for automobile manufacturing, as well as in completely knocked down plants with low-volume products, Intelligent products for industries to achieve the decentralization of the production through technology.

5.3 DIGITAL SUPPLIERS

It looking to build business networks to have common vision to bring their key business partners on a platform aiming at the creation of an easy interaction point, agile supplier onboarding using cloud technologies.

5.4 DIGITAL LOGISTICS AND INVENTORY

Digital Logistics and Inventory [8] considering technology assisted Real-Time Geo-Located Shipping using real-time tracking of their trucks, containers, and expensive products. Usage of robots for commissioning and spare parts business, application of robots in manufacturing and logistics. Usage of drones for an automated delivery but are least preferred in manufacturing, Augmented Reality and wearables for Picking and Commissioning but are not in an urgency to adopt, to extend allocation and order promising to the deployment of real-time planning and execution platforms that enable complex rule-based allocations multiple times a day, intelligent shelves to improve their VMI efficiency after reaching level of maturity to deploy technology.

5.5 DIGITAL IT AND TECHNOLOGY

Digital IT and Technology already moving towards an on-demand business IT as a general trend using cloud computing.

5.6 DIGITAL HR AND TALENT

This aims to put into practice mobile based talent development and training combined with Cloud capabilities and digital library into a mobile platform and wearable technologies for performance tracking when technology adoption matures.

5.7 DIGITAL PERFORMANCE MEASUREMENT SYSTEMS

Digital Performance Measurement Systems around end-to-end supply chain to be a key asset and a requirement to improve transparency and visibility using supply chain control towers and digital board rooms. Technological advancement help improve not only sales through data analysis but also efficacy and efficiency of production lines. Real-time granular data significantly improve planning and decision-making abilities. Wearable gadgets support the employees to meet their target. To lag and be closed to the opportunities that the new technologies offer is a major risk for the companies in digitalized economy.

6. TECHNOLOGIES RELEVANT TO SUPPLY CHAIN

“Emerging technologies are new technologies that are currently developing or will be developed over the next five to ten years, which will substantially alter the business and social environment” [8]. There are various technologies available and emerging day by day. When it comes to technology it is always important to understand whether it is a toy or tool. If it is having a toy value, then the time is not mature enough to invest on it. If the toy becomes tool means got enough gravity to consider it in business and not left behind the competition by not taking advantage of it at earlier stages. Most of the technologies are not new to the world but these technologies are transforming into new forms as the maturity and affordability makes us to consider those technologies to business from research labs.

Following technologies are worth a watch and adoption,

- Cloud Computing

- Internet of Things

- Blockchain

- Machine Learning

- Networked business

- Big Data

- In-Memory Computing

- Predictive Advanced Analytics

- 3D Printing

- Robotics

- Mobile

- e-Commerce

- Social Media

In this article, we assume and leave it to the reader’s interpretation and wisdom on various technologies and our intent is not to cover the definition of those topics rather our interpretation of applicability of those with few real-world problems faced by the current supply chain.

6.1 CLOUD COMPUTING

Cloud Computing [13] offers freedom to the business from worrying about how to manage on the infrastructure point, the relevant software requirements, installation and maintenance hurdles rather than what do you want to achieve in terms of value the idea could bring into business. Most of the time the resistance used to be the initial capex investments. This kills the idea and brings in a negativity of approaching the idea which could improve the business. Businesses could manage to secure the funds that are required to experiment new ideas in a perpetual way and if the ideas bring value that is proved through those experiments can be scaled without any reimplementation effort which may come from the infrastructure point of view. That way the pay as you use model helps business to free up the precious funds getting locked at the initial stage as the value realization takes longer time and getting perpetual model gives more agility as the value realized pays the cost of running which means flipping the coin to your favor. There is no vendor lock in and you are free to choose the vendor of your choice to be your partner.

6.2 INTERNET OF THINGS

IOT [12] brings in a newer dimension to business as you don’t have to wait for the manual data collection to make interpretations of business events. Often the lack of data brings mistrust and frustration when you try and take data backed decisions. Often this leads to a post facto analysis rather a smarter business decision to be future proof. When it comes to internet of things it is always perceived that we need to have sensors everywhere. But the fact of the matter is the internet of things doesn’t mean always sensor it is about data that could potentially makes sense if it received on time when the business event happens to interpret. By this definition all the existing data silos and the newer forms of data will be put into good use by collecting in an efficient manner, which gets qualified while ingesting to make sense to business. When it comes to internet of things the proof in pudding is in the interstellar space where voyager which was launched more than 4 decades before still talks to NASA and making business sense and decision to it. Due to technology advancements and affordability of such technologies to get applied to businesses bring those innovations out of research labs to business houses seamlessly.

6.3 BLOCK CHAIN

Block chain [9] works on the fundamentals of linked list and have sound potential to bring in transformation in supply chain space. This will eliminate lots of in-built inefficiencies due to latency built by people, file movement, restricted workflow by not considering of stakeholders at appropriate stages of business, iterative feedback loop which is not linked to timebound actions, transparency issues and bulk of documentation and access to those documentations by few and the extract getting passed on to required levels which adds to the bureaucracies in business. Block Chain attempted to solve many of those lacunas in the form of time bound or majority based consensus building framework, identity management to be part of the transaction, alteration free transactions as every transaction modification have a time bound feedback loop and consensus building and once approved by stakeholders becomes binding and transparent. That way every transaction is considered as block and once consented and approved becomes a linked list forming the block chain. All transactions right from requirement to retire have potential to embrace this technology which are traceable at any point in time by all stakeholders in the form of hyper ledgers. All contractual documents will go through this process. All of this gets through smart contracts as every interaction becomes a cycle of smart contract workflow. The crypto currency is another potential disruptor from the block chain initiative but have regulators receptiveness in its impact will delay getting adopted into the entire blockchain flow in business.

6.4 MACHINE LEARNING

Machine Learning [14] is an algorithmic approach which could free the limitation of human ability of thinking beyond certain level of possibilities on a given circumstances of business. Machine learning not only make sense out of an event but also could get the best action possible for a given circumstances and if implemented properly will also initiate action spot on. Since this technology is experimented in business newly and to minimize the impact of human irrelevance you may choose to implement in the form of supervised and unsupervised option. Many machine learning approach works based on game theory of recognize and reward principle and it will be a good to start with supervised learning for actions till the confidence level reached to the desired level of outcome. Potential areas of implementation are fraud detection, manufacturing, demand sensing for requirements, maintenance, operation, hiring, talent sensing and identifying training requirements, support, help desk, etc.

6.5 NETWORKED BUSINESS

Networked Business [15] also widely referred as smart business or connected everything which brings in dynamism in the current business process by moving process from silos to collaboration while conducting business. This also addresses the problem of multiple framework used by business and still have a chance of inconsistent information dispensing in business transactions. While you run your business on the traditional ERPs but allowed to interface with smart business framework based business for collaboration not only enterprise wide but also from the stakeholders outside your enterprise to collaborate which brings in transparency, secure, fast, efficient and complaint. This calls for connected businesses in every possible way. Cloud computing, Blockchain, IOT, ML are the contributing factors of networked business frameworks. Most popular among procurement, workforce management, travel and expense management, automatic replenishment of goods, maintenance and services, etc.

6.6 BIG DATA

Big Data [10] [11] as in its name is big in variety, velocity, volume to support and handle most forms of data. This also comes with tools that are required to make sense of the data. In the context of business, it doesn’t matter how big and how variety it is if doesn’t provide insights relevant to business considering of enterprise data. Now the data is available everywhere in the enterprise and in silos and have different owners who got different functions and priorities in business. There may be technological limitations to acquire and interpret the data which they own along with enterprise data. Fewer examples of such data are machine logs, manufacturing systems log, operations log, maintenance logs, SCADA data, building management system data, inspection data, metering data, videos, operations and maintenance manuals, installation guide, ACAD drawings, PDM drawings and data, call logs, Historians, etc. which in isolation make sense only to user of the respective system. But the real value to business is its interoperability at ease which brings in newer insights and early warnings for better planning and execution at various levels in real time non-intrusively. Businesses are interested to know how their product and services are accepted, its usage, failures, sourcing defects, expectations, sentiments, process defects while manufacturing and automatic correction of it, synchronized undiluted design to manufacturing experience, customer churn, newer product ideas etc. from where ever the data is available which could potentially give the insights.

6.7 IN-MEMORY COMPUTING

In-memory Computing [16] breaks the ceiling of the limits posed by technology all through years. This augments the adoption of certain technological innovations embedded into business where the needs are restricted by expensive computing resources. As we all know the computers or the laptops what we hold these days are much more powerful than the mainframe super computers of yester years. This brings in the possibility of new use cases for businesses to handle apart from the traditional business transactions and analytics. There are new terminology emerges such as trans-analytics where you don’t need to get off from your transaction systems to get analytics as the same can be provided everywhere. The data centers are becoming slimmer and energy efficient and scales to greater sizes. The real-time is real with this as there is no need to worry about the size of the data to get insights and no need to optimize the analytical objects as the computing power offsets those unwanted efforts which otherwise have a huge overhead in terms of skills. Storages have become 10 times slimmer and response times are faster by 10 to 100x times with right sized computing platforms. Though the price points are very low for the sizes business need which are further made accessible to all through cloud computing offerings as well. Business applications and process are taking advantage of this technology and comes out with innovative ready to consume business applications.

6.8 PREDICTIVE ANALYTICS

Predictive Analytics [17] which is perceived as advanced analytics and businesses are keen investing in recent days. The canned reports, dash boards and pre-processed reporting are not good enough for business as it got a reactive actionable value. Though it worked in the past the current changing business scenario it won’t help businesses maintain their lead and edge without predicting the outcomes data backed in real-time. The decisions not only made using human intelligence but also requires algorithmic backing and a quickly visualizing the information. All traditional business application vendors understood this aspect and providing predictive insights in their standard offerings. This trend is going to continue in future as well and this one area is well recognized by businesses on its value addition to core.

6.9 3D PRINTING

3D Printing [8] is an innovation which is quickly catching up in the manufacturing and service management sector as it offers enormous opportunity and helps innovation at fast pace without the tradition manufacturing methods applied with lot of lead times. This creates market for newer material compositions and the turnaround times are very less for even a complex component. This involves manufacturing organization achieving complete integration from design to production and quicker correction in the newer product development cycles. Business deeply involved in manufacturing and services can quickly respond to design deficiencies as they need to make modifications on design, print the component in question and test it quickly to respond to customers as well the current production line saving millions in product recalls. Outdated model and personalization of product is a possibility and created a newer market as it does not need to go through full product development and test cycles.

6.10 ROBOTICS

Robotics [4] is an area where large and modern manufacturing facilities were embracing from time and again. Now with the modern software based configurations it is even becoming better and can be tasked to even complex manufacturing processes. Current state of affair is semi-automation and pre-programmed process which are not considering the variables that may affect the physical built of the process and requires human intervention in fixing minor issues and quality assurance area. Recent days’ businesses are trying to achieve complete automation of manufacturing even post operation processing of moving from one workstation to another workstation which was considered one of lead-times generally not in control. To achieve full automation one need precision planning of all the activities involved in the entire supply chain which is impossible without technology. The manufacturing real-time data is crucial in adjusting the parameter to achieve the desired outcome using manufacturing intelligence data coupled with machine learning. The vision is to achieve zero human automated plants in future and technology is the key to success.

6.11 MOBILE

Mobile revolutionizes the supply chain scenario in enterprises where businesses need not get tied to their systems to respond or manage the processes involved in supply chain. This provides agility to the supply chain professionals and there are applications for enterprises built to perform certain functions where ever they are in a safe and secure manner and make them productive. The interesting aspect is don’t follow the business rather let the business follow you virtually. The trainings, learnings, time and attendance, mails, web conferences, workflow approvals are on your hand and the mobile phone is no more a mobile phone rather a virtual office in your pocket helps you do perform your businesses better.

6.12 E-COMMERCE

e-Commerce [19] matured from a stage of e-portal of busy bridge days to the current level. Supply chain don’t need to worry about vendor selection, inspection, qualification, rating, quality, delivery, returns etc. as it is available for most of the components that are required to run the supply chain efficiently. The e-commerce is matured from selective commodity led port to consumer goods to everything including the cars of modern aged and almost all commodities are available in one stop shop. The e-commerce of today not only extended to sourcing but to sell the goods and services what you produce which will eliminate layers of bureaucracy and the make the supply chain more dynamic and predictable. This also brings in competition as the bulk buy prices are offered at retail purchases too and the logistics is eliminated as it is part of the supply itself.

6.13 SOCIAL MEDIA

Social Media [15] is an important element of technology as the analysis of selling patterns and buying behavior is very attractive to all industries, because it allows a better understanding of customers’ requirements through demand sensing and up-to-date sales information. The thumbs up and down speak lot more than a thousand words and gestures and it is so hard to ignore it.

7. STUDY FINDINGS ON SHORTFALL IN SUPPLY CHAIN

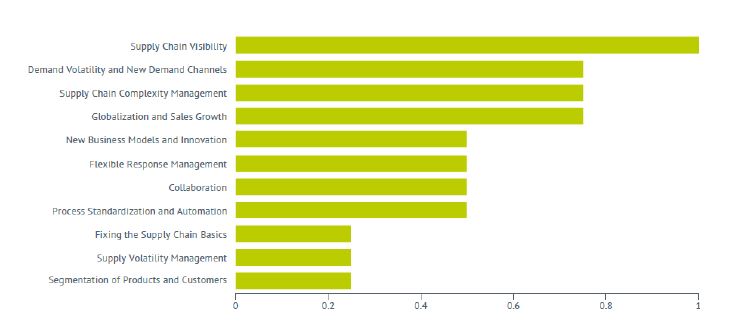

The methodology adopted to study the shortfall in supply chain is observation and interview methods through various engagements during study. Based on the observations a structured common denominator of relevant questions cutting across industries are made and the observations are recorded for analysis. Based on the data and its inference following are the critical outcomes that are summarized in Fig.6 below. Each parameter of observation is graded in a scale of 1.0 being the highest rating. The identified sample of prominent industry CXO’s and supply chain leaders and visionaries representing various industries from 25 industries are observed during extensive interviews.

While interpreting the results, Lack of supply visibility is one most common issue viewed across industry followed by demand volatility and new demand channels, complexity management, globalization and growth shares equal weightage. New business models and innovation, flexible response management, collaboration and process standardization and automation falls in the next level of priorities weighing equally. Though lower in ranking fixing the supply chain basics, supply volatility management and segmentation of products and customers are not ignored and given priority as future readiness factors. The study reveals that all these problems are believed to be addressed through technology that are discussed in this article and most of the vendors taking this opportunity seriously to fix it to help business become completely digital in the coming years. The journey is begun already. The technology adoption from the above will be perpetual and based on business relevance and are not based on eye catching jargons as discussed in the relevant technology sections in this article. The industries which will have a frenzy adoption are automotive OEMs and suppliers, machinery industry, consumer product goods, high tech industry, healthcare and life sciences as the changes are rapid in these industries.

8. CONCLUSION

This article intends to bring the importance of changing business scenarios and the organizational preparedness to embrace changes by constantly getting exposed to technology changes keeping the business benefits in mind. The leaders need to create sufficient budget and skills to handle the change as non-intrusive as it can by focusing on the maximum lever of benefit vs technology and invest in a systematic manner in the right investment buckets incrementally to prepare and sustain the businesses in the future.

REFERENCES

[1] Industry 4.0 at McKinsey’s model factories, Available at: https://capability-center.mckinsey.com/files/mccn/2017-03/digital_4.0_model_factories_brochure_2.pdf

[2] Poorya Farahani, Christoph Meier and Joerg Wilke, “Digital Supply Chain Management 2020 Vision”, White Paper, pp. 1-52, 2017.

[3] Industry 4.0: Building the Digital Industrial Enterprise, Available at: https://www.pwc.com/gx/en/industries/industries-4.0/landing-page/industry-4.0-building-your-digital-enterprise-april-2016.pdf

[4] Ying Yu, Xin Wang and Ray Y. Zhong, “E-commerce Logistics in Supply Chain Management: Practice Perspective”, Procedia CIRP, Vol. 52, pp. 179-185, 2016.

[5] Gerhard Oswald and Michael Kleinemeier “Shaping the Digital Enterprise: Trends and Use Cases in Digital Innovation and Transformation”, Springer, 2016.

[6] C. Chandra, “Supply Chain Configuration: Concepts, Solutions, and Applications”, Springer, 2007.

[7] Lourdes Mary Amulu and Ravi Ramraj, “A Novel Fuzzy Bayesian Approach for Energy Efficient Management of Scientific Workflows in Cloud”, Journal Perspetivas in Information Science, Vol. 22, No. 4, pp. 23-29, 2017.

[8] Michael J. Ryan, Daniel R. Eyers, Andrew T. Potter and Laura Purvis, “3D Printing the Future: Scenarios for Supply Chains”, International Journal of Physical Distribution and Logistics Management, Vol. 47, No. 10, pp. 992-1014, 2017.

[9] Niels Hackius and Moritz Petersen, “Blockchain in Logistics and Supply Chain: Trick or Treat?”, Proceedings of Hamburg International Conference of Logistics, pp. 1-23, 2017.

[10] J. Barjis, R. Pergl and E. Babkin, “Enterprise and Organizational Modeling and Simulation”, Springer, 2015.

[11] Daniel Q. Chen and David S. Preston, “How the Use of Big Data Analytics Affects Value Creation in Supply Chain Management?”, Journal of Management Information Systems, Vol. 32, No. 4, pp. 12-18, 2015.

[12] P. Suresh, J. Vijay Daniel, V. Parthasarathy and R.H. Aswathy, “A State of the Art Review on the Internet of Things (IoT) History, Technology and Fields of Deployment”, Proceedings of International Conference on Science Engineering and Management Research, pp. 723-729, 2014.

[13] Anthony Clervi, “Cloud Computing Is Transforming Supply Chain Management”, Available at: https://www.sdcexec.com/sourcing- procurement/article/12125647/cloud-computing-is-transforming-supply-chain-management, Accessed on 2015.

[14] AI in the Supply Chain: Logistics gets Smart, Available at: http://www.cio.in/feature/ai-supply-chain-logistics-gets-smart.

[15] Richard Howells, “How the Network Economy Is Revolutionizing Supply Chains”, Available at: https://www.weforum.org/agenda/2015/01/how-the-network-economy-is-revolutionizing-supply-chains/

[16] Gary Brooks, “How Predictive Analytics Will Change the Supply Chain of Tomorrow”, Available at: https://tdwi.org/articles/2018/01/19/adv-all-how-predictive-analytics-will-change-supply-chain-of-tomorrow.aspx.

[17] John Santagate, “NextGen Supply Chain: The Robots are Here”, Available at: http://www.scmr.com/article/nextgen_supply_chain_the_robots_are_here.