GREEN SUPPLY CHAIN INITIATIVES OF MANUFACTURING FIRMS: COMPLEMENTARY VERSUS TRADE-OFF

C. Ganeshkumar1 and G. Madan Mohan2

1Indian Institute of Management Bangalore, India

2Department of Management Studies, Pondicherry University, India DOI:

10.21917/ijms.2015.0009

Abstract : Organizations throughout the world are persistently striving hard to develop new and innovative ways to enhance their performance and competitiveness. Effective green supply chain management (GSCM) has become a potentially valuable means to secure competitive advantage and improve performance of the firm in the global market place. GSCM also helps to sustain natural ecosystems and human populations with a high standard of living. This research conceptualizes and tests the dimensions of green SCM practice, competitive advantage, and performance dimensions. Data for the study were collected from 62manufacturing organizations and the relationships proposed in the framework were tested using Partial Least Square (PLS) -Structural Equation Modeling and moderating effects through Sobel Test. The results indicate that green SCM practices have a positive impact on competitive advantage and performance of the manufacturing enterprises.

Keywords: Green Supply Chain Management, Path Modeling, Performance, Competitive Advantage1. INTRODUCTION

Green supply chain management (GSCM) is emerging as an imperative organizational concept to facilitate organizational performance and effectiveness by plummeting environmental risks and bearings by refining their ecological competence. Organizations all over the globe are striving hard to enhance their competitiveness through novel and pioneering means (Srivastava, 2007). Environmental and Supply Chain Management have assumed indispensable proportions in the recent past for competitiveness and success of any organization. Multinational companies have established distribution channels worldwide to avail the economies of operating in specific country-industry and thereby build competitive advantage (Seuring and Müller, 2008).Furthermore, stern legislative protocols and enhanced awareness on the part of consumers and public on environmental issues, industrialists are forced to effectively assimilate environmental apprehensions into their routine businesses and formulation of strategic plans and policies. For instance, In India, Procter & Gamble produces incense sticks while Tata Motors pavement bricks as by-products from the wastes generated from their routine production activities (Sangameshwaran, 2013 & Bajdor and Grabara, 2011). Modern day industrialists have recognized the importance of assimilating environmental concerns and Supply Chain management to win and preserve competitive advantage and enhance their organisation’s performance. Hence, in addition to business managers, academicians and consultants have started attaching paramount importance to the concept of Green SCM (Sarkis et al, 2011). Similarly, numerous organisations have started recognizing the importance of Green SCM to facilitate building a viable competitive superiority for their products over their rivals in an extensively competitive market environment (Hervani et al, 2005). Emphasizes that firms recognizing that Green SCM shall result in an improved performance and competitive advantage, alone shall implement the Green SCM (Rao and Holt, 2005). Hence, it can be observed that a close relationship exist between implementing Green SCM and heightened competitiveness and boosted performance of business enterprises and this study tries to establish this strong association by measuring the impact of such association by implementing the Green SCM practices in business policies. Numerous business enterprises in India have endeavoured to start implementing green SCM initiatives. Prior research have examined the inspiring and stirring factors behind these initiatives on the part of business enterprises (Besley and Burgess, 2004).However, the relationship between such green initiatives and enhancement in performance and competitiveness have not been examined empirically in Indian context. This paper endeavours to address this gap by surveying manufacturing enterprises in India to examine hypothesis that significant connection exist between greenlining some components of the supply chain and enhancement in performance and competitiveness and to test empirically whether Green SCM initiatives have complementary or trade-off effects on performance and competitive advantage of manufacturing industries. The paper begins with an exploration of prior studies on various aspects relating to GSCM and based on which a theoretical model of GSCM, performance and competitiveness is constructed in section 2. Section 3 throws light on the Methodology used to test the casual links between the constructs of conceptual model using structural equation modeling (SEM).Section 4 highlights results of this study. Finally, sections 5 and 6 conclude the discussion by summarizing the findings and highlighting the implications, limitations and potential topics for future research.

2. LITERATURE REVIEW AND RESEARCHFRAMEWORK

The forthcoming paragraphs present the literature support and various linkages among Green supply chain management practices, performance and competitive advantage of manufacturing industries.

2.1 GREEN SCM PRACTICES

Preemptive and principal manufacturing enterprises are utilizing Green SCM as their operational management tool to accomplish their desired goal. GSCM practice operation arrays from green purchasing to reverse logistics. Numerous definitions may be quoted for Green SCM (Zhu et al, 2008;Hsu et al, 2013). Srivastava (2007) talks about various facets to measure GSM practice operation, i.e materials acquisition, preproduction, production, use, distribution, and disposal. Sarkis (2011) established a strategic decision outline for operationalization of GSCM practices to appraise alternatives implemented by enterprises which might have an effect on their exterior associations with suppliers and customers and Zhu and Sarkis (2004)examined the link between GSCM practices operationalisation and performance, focusing on the moderating effects of quality and just-in-time (lean) practices and Zhu et al (2007)conducted a study on some 314 Chinese business enterprises and arrived at clusters of GSCM pressures, practice and performance. Based on previous studies, Zhu et al (2008)formulated and authenticated the GSCM practices and conceptualized five dimensions namely, Internal environmental management, Green purchasing, Cooperation with customers, Eco-design and Investment recovery. These dimensions have been used in this research work.

2.2 SUSTAINABLE PERFORMANCE

GSCM practices encompass initiatives on diminishing emission of greenhouse gas through a thorough scrutiny of suppliers’ environmental performance, concentrating on producing eco-friendly products, eliminating usage of hazardous materials in packaging and minimizing wastage in the process of production and distribution. The process of greening the supply chain involves integration of environmental criterion and apprehensions into organizational buying decisions and long-term relations with suppliers (Darnall et al, 2008). Gold et al (2010) points out the manner in which suppliers can contribute to environmental modernization through a wide range of activities which may include materials handling, manufacturing, warehousing and preserving, packing, transporting and distributing and technology acquisition and transfer to suppliers. Modern organisations operating globally are required to maintain a sustained customer-relationship management, supplier-relations management and internal supply chain through effective Green supply chain practices. Outsourcing of both core and non-core business activities have become order of the day for many industrial establishments, irrespective of their size and magnitude of operations. This necessitates the need to maintain an effective GSCM on the part of all components of the supply chain, including suppliers and customers. This becomes absolutely indispensable considering the turmoil and challenges posed by the prevailing economic environment. Working out an acceptable, effective and justifiable solution to business problems is not an easy issue. Emphasis on environmental issues may lead to other consequences. For instance, emphasis on diminishing energy utilization during the usage phase may not result in any economic favour if it is accompanied by an increased energy consumption during the manufacturing and recycling phase (Rao and Holt, 2005) and Dey and Cheffi (2012) analysed the GSC performance of establishments and arrived at comprehensive definitions about the three concepts of Environmental, Economic and Operational performance and these dimensions have been used in this research work.

2.3 COMPETITIVE ADVANTAGE

The capacity of an industrial undertaking to generate a distinguishable unassailable position over its competitors through precarious management decisions are termed as “Competitive advantage” (Sarkiset al, 2011). Price/cost, delivery, quality and flexibility have been well identified as vital competitive competences of business enterprises (Li et al, 2006). Time-based competition has also been included as an important component of competitive advantage by latest studies. Rao and Holt (2005) has developed a research framework for testing the relationships between competitive and performance. Extensive review of available literature has resulted in the arriving of cost/price, delivery dependability, product innovation, quality and time to market as the dimensions used under competitive advantage constructs hence Li et al (2006)dimensions have been used in this research work.

2.4 INTER-RELATIONSHIP BETWEEN GREEN SUPPLY CHAIN, COMPETITIVE ADVANTAGE AND PERFORMANCE

Rao and Holt (2005) has found that South East Asian organisations have started using eco-friendly raw materials thereby greening their production process; emphasize on cleaner environment through reduced pollution and wastage in their income generation logistics activities; implementing greening of outbound logistics through eco-friendly waste disposal and waste water treatment and reducing emission of greenhouse gases to mitigate dangers of pollution. These measures enable organizations fulfill their social responsibility of improving environmental conditions as well as ensure their compliance with environment regulations, which shall eliminate threat of imposition of penalty and closure. Hence, it can be observed that numerous studies exist examining the impact exerted by greening measures in the supply chain while some have unearthed the business and economic effects of environmental performance of firms (Green et al, 2006). However, the relationship between GSCM measures of business organizations and improvement in their competence and economic performance have not been examined clearly. This position is no different in US and Europe. This study tries to go into the area where no prior research has been conducted and this makes the proposed research work exploratory and purely original in the South East Asian context.

Rich literature talks about the operationalization of competitive advantage and enhanced performance due to Green SCM (Markley and Davis, 2007). Rha and Holt (2005) found that GSCM practices have a significant positive relationship with supply chain performance parameters and Green et al (2006) have studies a causal study of GSCM, environmental and economic performance dimensions by collected primary data of 159 executives manufacturing industry and tested with structural equation modeling and results shows that adoption of GSCM will impact the environmental and economic performance. Luthra et al (2013) categorizes the GSCM implementation strategies into four dimensions namely, Non members of supply chain, downward stream supply chain Members, Organizational members of supply chain and upward stream supply chain members. These dimensions are found to play an important role in greening the supply chain enabling the practicing firms achieve enhanced operational performances and Lee et al (2012) explored the effect of GSCM practices on organizational performance of 223 small and medium Korean enterprises engaged in Electronics, using three organizational variables of employee satisfaction, operational efficiency and relational efficiency as moderators. Results revealed the prevalence of significant indirect relationship between GSCM practices implementation and business performance through mediating variables of operational efficiency and relational efficiency, indicating that business performance will improve when GSCM enhances operational efficiency.

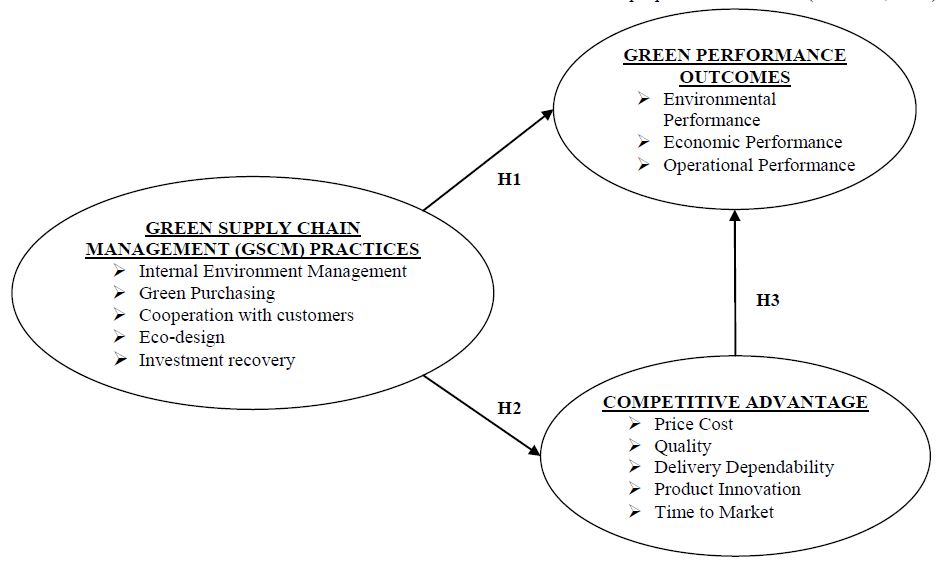

Available literature support has been utilized to establish the link between Green SCM practices, competitive advantage and green performance have been elaborated and tentative hypotheses pertaining to these variables have been developed, hence many research studies have been conducted to explore GSCM initiatives on the part of business organizations. However, very little research has been conducted on examining the impact of GSCM on the performance and competitive advantage of business enterprises. Business organizations will be reluctant to observe GSCM unless it is doubtlessly proved that GSCM exerts a significant and unambiguous impact on their performance and competitive advantage. Fig.1 portrays the Green SCM, performance and competitiveness of manufacturing enterprises framework developed in this research. The framework proposes that Green SCM practices will have a direct and indirect impact on green performance through competitive advantage.

2.5 RESEARCH HYPOTHESES

H1: Firms with high level of GSCM practices will have high level of performance.

H2: Firms with high level of GSCM practices will have high level of competitive advantage.

H3: Firms with high level of competitive advantage will have high level of performance.

H4: The impact of GSCM practices on performance is moderated by the competitive advantage.

3. RESEARCH METHODOLOGY

The proposed research is descriptive in nature, based on primary and secondary data. Secondary data have been collected from various research articles, relating to prior research studies conducted on the field of GSCM and its effect on performance and competitive advantage of business firms. Primary data have been collected by administering personally, a well structured interview schedule to executives of 62ISO14001 certified manufacturing enterprises, which were selected at a random from the list of manufacturing enterprises obtained from the Department of Industries and Commerce, Government of Tamil Nadu, India. It was ensured that the executives selected for this study were highly knowledgeable about the operations and supply chain management of their respective enterprises. The interview schedule developed was initially tested for item reliability. Content validity is absolutely necessary for any measurement instrument which can be ensured only if the measurement items used in the instrument cover major portion of the constructs proposed to be studied (Hair et al, 2009).

The response of the business executives about GSCM, competitive advantage and performance of their enterprises were collected using a Likert’s five point scale and suitably represented in tables. The data so collected were analysed scientifically using the statistical tools of PLS-SEM analysis by using SmartPLS software, which is based on variance rather than covariance base statistical tool. PLS is the suitable analytical tool for this study due to some reasons. First, in PLS, minimum of three items is sufficient to measure a construct, while in covariance-based approaches, a minimum of four variables are required. Secondly, PLS needs no normality assumptions and handles minimum sample size of 30 (Hair et al, 2009) and Fig.2 illustrates various phases involved in the present research work which are given below.

4. RESULTS AND DISCUSSION

First part of the analysis shall test the reliability and validity of the constructs used, while in the second step, the casual relationship among the proposed constructs are established by testing the structural model by assessing fitness of the overall model fit.

4.1 RELIABILITY AND VALIDITY OF CONSTRUCTS

To begin with, the internal consistency reliability is checked using the traditional criterion of Cronbach’s alpha, which provides an estimate for the reliability based on the indicator inter-correlations. The PLS path model uses composite reliability. Composite reliability takes into account that indicators have different loadings and can be interpreted in the same way as Cronbach’s alpha. Irrespective of usage of different reliability coefficient, an internal consistency reliability value above 0.6 is satisfactory (Hair et al, 2009). Table 1 displays the values of Cronbach’s alpha and composite reliability, which seems to exceed the minimum requisite of 0.6, which establishes the internal consistency and reliability of the proposed measurement model. Furthermore, validity of the model can be assessed using convergent validity and discriminant validity. The former certifies that the variables used (known as observed variables) represent the construct (known as Latent variable) adequately. Hair et al (2014) suggested that the average variance extracted (AVE) and the factor loadings in respect of the items should around the 0.5, indicating that the observed variables are able to explain at least 50% of the Latent variable, signifying there is sufficient convergent validity. Table 1 portrays the factor loadings and AVE measurements of each constructs. It can be seen that there is strong convergent validity as all the values exceed the threshold limit of 0.5.The next step is to test the discriminant validity, for which the square roots of AVE for individual constructs exceed the correlation between a construct and any other construct(Hair et al, 2012). Table 2 displays the correlation between constructs with square root of the AVE on the diagonal. Since all the diagonal values exceed the inter-construct correlation, discriminant validity is proved and it can be inferred from the two tables that the constructs possess both discriminant and convergent validity, and hence it can be concluded that adequate construct validity exists in the proposed model with respect to data collected using structured questionnaire from the manufacturing firms.

The individual path coefficients of the PLS structural model can be interpreted as standardized β coefficients of ordinary least squares regressions. The result of the structural model analysis is portrayed in Figure2 while Table.3 depicts the causal linkage among GSCM practices, competitive advantage and performance of the organization. Results and discussion of path model using PLS structural equation modeling has been portrayed in the following part.

4.2 RESULTS FOR THE STRUCTURAL MODEL

The theoretical framework illustrated in Fig.3 and Fig.4 has three hypothesized relationships among the variables, Green SCM Practices, Competitive Advantage and Performance of the manufacturing enterprises. The results exhibit that all the measurements have significant loadings to their corresponding construct. It may be noted that all the t-values of the measurements items are significant at 5 percent level; their loadings (r-value) to the corresponding construct are different.

Results of path analysis relating to the testing of the hypotheses are displayed in Table.3.

The Fig.2 portrays the three causal relationships of GSCM practices and performance; GSCM practices and competitive advantage; competitive advantage and performance while the relationships has been represented in tabular form in Table 3. the beta value and t-value displayed by the table in respect of the three relationships establish that GSCM has positive causal relationship with performance, GSCM practices have a positive causal relationship with competitive advantage and competitive advantage have a positive causal relationship with performance of the manufacturing enterprises.

4.3 GOODNESS OF FIT CRITERION (GOF) OF PLS-SEM MODEL

In order to validate the proposed model Tenenhaus et al (2004) suggested use of GoF index which refers the geometric mean of the average communality and average R-square. This index is similar to Chi-Square fit index applied in Covariance based SEM using LISREL/AMOS software. This study will use this index to validate the global measurement of the proposed conceptual model. The GoF index is calculated as GoF=√Avg(Communality) * Avg(R2) (Tenenhaus et al, 2004). The score of GoF will be ranges between 0 and 1 (0 ≤ GoF ≤ 1) (Daryanto et al, 2009). In order to set up the baseline for GoF, the study refers into the technique used by Daryanto et al (2009). First of all, the cut-off value for communality of each construct in the model was set at value around 0.5 (Fornell and Larcker, 1981). Table 4 shows the GOF values of three constructs used in this research work.

Daryanto et al (2009) proposed that the baselines for GoF are small = 0.2, medium = 0.13 and large = 0.36. The calculation of GoF index for the proposed conceptual model has yielded a score of 0.74. Since the GoF index model is having a value of 0.74 and it is above the Large Fit score of 0.36, the model can be considered as a robust fit and it is valid for global measurement.

4.4 STRUCTURAL EQUATIONS OF CONCEPTUAL MODEL

The following equations derived from results of overall structural model portrayed by Fig.4 can be used to assess the degree of causal sustainable performance, Green supply chain practices and competitive advantage of manufacturing enterprises.

Sustainable performance = 0.74 (Green Supply Chain Practices) + 0.15 (Competitive Advantage)

Competitive Advantage = 0.59(Green Supply Chain Practices)

The first structural equation explores the casual relationship among sustainable performance, green supply chain practices and competitive advantage. Sustainable performance act as exogenous or dependent variable for green supply chain practices and competitive advantage, which act as exogenous or independent variables. The first linear equation displays the extent of influence exerted by green supply chain practices and competitive advantage. Result depicts that 74% variance in sustainable performance is dependent on Green supply chain practices; while 15% variance in sustainable performance is dependent on competitive advantage and finally 59% variance in competitive advantage is dependent on Green supply chain practices. Furthermore, the significance value is less than 0.01, suggesting that the result is absolutely reliable. These results suggests that any manufacturing undertaking endeavouring to enhance their sustainable performance and competitive advantage should give paramount priority to improve their Green supply chain initiatives in the organization especially Internal environmental management, green purchasing and Eco-design practices of manufacturing industry to complement the sustainable performance and competitive advantage of manufacturing firms.

4.5 SOBEL TEST FOR TESTING MEDIATING EFFECTS

The Sobel test is used to examine the existence of significant mediation effect. Under Mediation effect, it is hypothesized that indirect relationship exists between the dependent and independent variables due to the impact of a third variable, “Mediator”. The inclusion of a mediating variable in Regression Analysis reduces the impact of independent variable while the impact of Mediator assumes significant proportions. The Sobel test is an advanced T-Test, which measures whether inclusion of mediator variable significantly diminishes the impact of independent variable, rendering the mediation affect statistically significant (Hair et al, 2009).

Sobel value in Table.4 shows insignificant that is greater than 0.1 Hence competitive advantage is acting as an effective mediating variable in the relationship between GSCM and Performance of manufacturing enterprises (Lowry and Gaskin, 2014).

5. CONCLUSION AND IMPLICATIONS OF THE STUDY

Many organizations have understood the importance of implementing GSCM practices. However, they have been incapacitated to implement such practices due to lack of understanding of the inclusive components of such GSCM practices. This study will be of immense utility to business managers to tide over this delectate situation. Furthermore, this study has clarified various issues related to GSCM practices which have not yet been consistently explained (Walker et al, 2008) The study has established that GSCM Practices of business organizations exert a direct impact on them gaining competitive advantage and boosting of performance. This stresses the importance of GSCM to business organizations. With nature of competition undergoing a paragon shift from “inter-organization” to “Inter-Supply chain”, emphasis on GSCM has become indispensable for organizations to gain competitive advantage, thereby boosting their performance. Stressing on the importance of GSCM, this study offers supply chain managers’ useful tool for assessing the exhaustiveness of the GSCM practices being implemented by their organizations. This paper provides empirical justification for a framework that identifies key dimensions of Green SCM practices and describes the relationship among Green SCM practices, competitive advantage and performance of manufacturing enterprises. The study has established that GSCM practices boosts the level of performance of business undertakings, implementation of GSCM practices enables manufacturing enterprises to gain competitive advantage and organizations with comparative advantage gain a boost in performance.

6. LIMITATIONS AND SCOPE FOR FURTHER STUDY

Limited sample size of 62 posed a constraint for the conduct of revalidation of constructs. Furthermore, lack of systematic confirmatory research hinders general agreement on use of the research instrument. Future studies can revalidate measurement scales used by this study. Furthermore, the notion of SCM is highly multifaceted, involving a cluster of enterprises striving for manufacturing and distributing products/services. It is almost impossible to cover its complete sphere in one study. Future studies can concentrate on an expanded area of SCM practice by taking into account, extra proportions such a cross-functional coordination, agreed supply chain leadership, JIT/lean capability, logistics integration and geographical proximity. Future research may study the inter-GSCM relations that may prevail among the five dimensions of GSCM. For instance, information sharing may necessitate the creation of a strategic supplier partnership. Further, this research has included only one respondent from each organization, which may lead to response bias. Future studies may include multiple respondents in each organization to tide over this limitation. Respondents from pairs of enterprises at the two extreme ends of supply chain may also be included for a future study. Further, a comparison of views of organizations forming part of supply chain of a particular organization may facilitate identification of weaknesses and strengths of the supply chain and the better common GSCM practice in the supply chain.

ACKNOWLEDGEMENT

The authors are thankful to the EADS-SMI endowed chair for sourcing and supply management of IIMB for partially supporting the study.

REFERENCES

[1] Paula Bajdor and Janusz K. Grabara, “Implementing" Green" Elements into the Supply Chain-the Literature Review and Examples”, Annales Universitatis Apulensis Series Oeconomica, Vol. 2, No. 13, pp. 584-589, 2011.

[2] A. Barve and K. Muduli, “Modelling the challenges of green supply chain management practices in Indian mining industries”, Journal of Manufacturing Technology Management, Vol. 24, No. 8, pp. 1102-1122, 2013.

[3] T. Besley and R. Burgess, “Can Labor Regulation Hinder Economic Performance? Evidence from India”, The Quarterly Journal of Economics, Vol. 119, No. 1, pp. 91-134, 2004.

[4] M.K. Chien and L.H. Shih, “An empirical study of the implementation of green supply chain management practices in the electrical and electronic industry and their relation to organizational performances”, International Journal of Environmental Science and Technology, Vol. 4, No. 3, pp. 383-394, 2007.

[5] Nicole Darnall, G. Jason Jolley and Robert Handfield, “Environmental management systems and green supply chain management: complements for Sustainability?”, Business Strategy and the Environment, Vol. 17, No. 1, pp. 30-45, 2008.

[6] P. K. Dey and W. Cheffi, “Green supply chain performance measurement using the analytic hierarchy process: a comparative analysis of manufacturing organizations”, Production Planning & Control: The Management of Operations, Vol. 28, No. 8-9, pp. 702-710, 2012.

[7] A.K. Digalwar, A.R. Tagalpallewar and V.K. Sunnapwar, “Green manufacturing performance measures: an empirical investigation from Indian manufacturing industries”, Measuring Business Excellence, Vol. 17, No. 4, pp. 59-75, 2013.

[8] S. Gold, S. Seuring and P. Beske, “Sustainable supply chain management and inter-organizational resources: a literature review”, Corporate Social Responsibility and Environmental Management, Vol. 17, No. 4, pp. 230-245, 2010.

[9] Green Jr. K. W, McGaughey R and Casey K. M, “Does supply chain management strategy mediate the association between market orientation and organizational performance?”, Supply Chain Management: An International Journal, Vol. 11, No. 5, pp. 407-414, 2006.

[10] K.W. Green Jr., P.J. Zelbst, J. Meacham and V. Bhadauria, “Green supply chain management practices: impact on performance”, Supply Chain Management: An International Journal, Vol. 17, No. 3, pp. 290-305, 2012.

[11] K. Green, B. Morton and S. New, “Green purchasing and supply policies: do they improve companies’ environmental performance?”, Supply Chain Management: An International Journal, Vol. 3, No. 2, pp. 89-95, 1998.

[12] V. Gupta, S. Bhakar, T. Bansal and R.K. Jain, “Green Supply Chain Management Initiatives by IT Companies in India”, The IUP Journal of Operations Management, Vol. 12, No. 2, pp. 6-24, 2013.

[13] J.F. Hair Jr., W.C. Black, B.J. Babin and R.E. Anderson, “Multivariate Data Analysis”, Prentice Hall, Upper Saddle River, NJ, 1998.

[14] A.A. Hervani, M.M. Helms and J. Sarkis, “Performance measurement for green supply chain management”, Benchmarking: An International Journal, Vol. 12, No. 4, pp. 330-353, 2005.

[15] P. Hong, H.-B. Kwon and J.J. Roh, “Implementation of strategic green orientation in supply chain: an empirical study of manufacturing firms”, European Journal of Innovation Management, Vol. 12, No. 4, pp. 512-532, 2009

[16] C.-C. Hsu, K.C. Tan, S.H.M. Zailani and V. Jayaraman, “Supply chain drivers that foster the development of green initiatives in an emerging economy”, International Journal of Operations & Production Management, Vol. 33, No. 6, pp. 656-688, 2013.

[17] I. Kim and H. Min, “Measuring supply chain efficiency from a green perspective”, Management Research Review, Vol. 34, No. 11, pp. 1169-1189, 2011.

[18] S.M. Lee, S.T. Kim and D. Choi, “Green supply chain management and organizational performance”, Industrial Management & Data Systems, Vol. 112, No. 8, pp. 1148-1180, 2012.

[19] S.-Y. Lee, “Drivers for the participation of small and medium-sized suppliers in green supply chain initiatives”, Supply Chain Management: An International Journal, Vol. 13, No. 3, pp. 185-198, 2008.

[20] S. Li, B. Ragu-Nathan, T.S. Ragu-Nathan T and S. Subba Rao, “The impact of supply chain management practices on competitive advantage and organizational performance”, Omega, Vol. 34, No. 2, pp. 107-124, 2006.

[21] S. Luthra, D. Garg and A. Haleem, “Identifying and ranking of strategies to implement green supply chain management in Indian manufacturing industry using Analytical Hierarchy Process”, Journal of Industrial Engineering and Management, Vol. 6, No. 4, pp. 930-962, 2013.

[22] M.J. Markley and L. Davis, “Exploring future competitive advantage through sustainable supply chains”, International Journal of Physical Distribution & Logistics Management, Vol. 37, No. 9, pp. 763-774, 2007.

[23] P. Rao and D. Holt, “Do green supply chains lead to competitiveness and economic performance?”, International Journal of Operations & Production Management, Vol. 25, No. 9, pp. 898-916, 2005.

[24] J.S. Rha, “The Impact of Green Supply Chain Practices on Supply Chain Performance”, M.A. Thesis, Business Administration, University of Nebraska-Lincoln, 2010.

[25] J. Sarkis, “A strategic decision framework for green supply chain management”, Journal of Cleaner Production, Vol. 11, No. 4, pp. 397-409, 2003.

[26] J. Sarkis, Q. Zhu and K.-H Lai, “An organizational theoretic review of green supply chain management literature”, International Journal of Production Economics, Vol. 130, No. 1, pp. 1-15, 2011.

[27] S. Seuring and M. Müller, “From a literature review to a conceptual framework for sustainable supply chain management”, Journal of Cleaner Production, Vol. 16, No. 15, pp. 1699-1710, 2008.

[28] S. Sindhi and N. Kumar, “Corporate environmental responsibility–transitional and evolving”, Management of Environmental Quality: An International Journal, Vol. 23, No. 6, pp. 640-657, 2012.

[29] S.K. Srivastava, “Green supply chain management: a state of the art literature review”, International Journal of Management Reviews, Vol. 9, No. 1, pp. 53-80, 2007.

[30] S. Vachon, “Green supply chain practices and the selection of environmental technologies”, International Journal of Production Research, Vol. 45, No. 18-19, pp. 4357-4379, 2007.

[31] S. Vachon and R.D. Klassen , “Environmental management and manufacturing performance: the role of collaboration in the supply chain”, International Journal of Production Economics, Vol. 111, No. 2, pp. 299-315, 2008.

[32] H. Walker, L. Di Sisto and D. Mcbain, “Drivers and barriers to environmental supply chain management practices: Lessons from the public and private sectors”, Journal of Purchasing and Supply Management, Vol. 14, No. 1, pp. 69-85, 2008.

[33] Q. Zhu and J. Sarkis, “Relationships between operational practices and performance among early adopters of green supply chain management practices in Chinese manufacturing enterprises”, Journal of Operations Management, Vol. 22, No. 3, pp. 265-289, 2004.

[34] Q. Zhu, J. Sarkis and K.-H. Lai, “Green supply chain management: pressures, practices and performance within the Chinese automobile industry”, Journal of Cleaner Production, Vol. 15, No. 11-12, pp. 1041-1052, 2007.

[35] Q. Zhu, J. Sarkis and K.-H. Lai, “Initiatives and outcomes of green supply chain management implementation by Chinese manufacturers”, Journal of Environmental Management, Vol. 85, No. 1, pp. 179-189, 2007.

[36] Q. Zhu, J. Sarkis and K.-H. Lai, “Confirmation of a measurement model for green supply chain management practices implementation”, International Journal of Production Economics, Vol. 111, No. 2, pp. 261-273, 2008.